Moto 530 / Moto 630

| Thicknessing Machine | MOTO 530 | MOTO 630 | |

| Max. working width | mm | 530 | 630 |

| Cutterblock diameter | mm | 120 | 120 |

| Max. cutting depth | mm | 8 | 8 |

| Feed speed | MT/1′ | 5-20 | 5-20 |

| Max. working height | mm | 300 | 300 |

| Number of knives | p- mm | 4p-30*530*3 | 4-30*630*3 |

| Cutterblock rotation speed | g/1′ | 4800 | 4800 |

| 3-phase motor power | HP (KW) | 7,5 (5,5KW) | 7,5 (5,5KW) |

| Power of the motorgear for rise/fall | HP (KW) | 0,5 (0,33KW) | 0,5 (0,33KW) |

| Feeder motor power | HP (KW) | 1,0 (0,75KW) | 1,0 (0,75KW) |

| Work table dimensions | mm | 1050 x 532 | 1050 x 632 |

| Min. working lenght | mm | 280 | 280 |

| Net weight | kg | 810 | 875 |

| Sound power level at operator’s site | db | 82,2 | 82,2 |

| Standard Accessories | MOTO 530 | MOTO 630 |

| Knife-setting device | ● | ● |

| 4 pcs planing knives | ● | ● |

| Motorized thicknesing table lifting | ● | ● |

| Sectioned feeding roller | ○ | ● |

| Optional accessories | MOTO 530 | MOTO 630 | |

| 1 Table roller | |||

| 2 Table rollers | Standard | ||

| Motor | HP (KW) | 10,0(7.5KW) | 10,0(7.5KW) |

| Control electroinstallations and quota volocita | MT/1′ | * | Standard |

| Feeding rollers rubber output | * | * | |

| Sectioned feeding roller | * | Standard |

Sega315 & Sega350

TECHNICAL DATA

STANDARD EQUIPMENT:

- LIFTING AND TILTING OF SAW UNIT BY MEANS OF HANDWHEELS ON THE MACHINE FRONT SIDE AND MECHANICAL READOUT OF SAW UNIT TILT

- ANODIZED ALUMINIUM ALLOY SLIDING CARRIAGE SLIDING ON HIGH PRECISION “ARCH-FORMED” HARDENED STEEL GUIDES, WHICH ARE FIXED ON THE CARRIAGE BY MEANS OF MECHANICAL BENDING SYSTEM

- SLIDING CARRIAGE LENGTH 3200MM

- EMERGENCY PUSHBUTTON LOCATED ON THE FRONT MACHINE SIDE •OVERLOAD PROTECTION

- BLADE PROTECTION ON RIVING KNIFE WITH EXHAUST OUTLET 60MM,

- INDEPENDENT POWERED SCORING UNIT WITH EXTERNAL SETTING UP AND STOPS FOR A QUICK RE-POSITIONING OF THE BLADE

- DIRECT START MAIN MOTOR WITH PUSHBUTTONS

- PADLOCKABLE MAIN SWITCH

- AVAILABILITY: EX-STOCK SUBJECT TO PRIOR SALE

| MAX CUTTING HEIGHT AT 90° (MM) | 100 mm WITH BLADE 350 | ||||

| MAX CUTTING HEIGHT AT 45° (MM) | 75 WITH BLADE 350 | ||||

| BLADE TILT (DEGREES) | 45 | ||||

| BLADES LIFTING AND TILT | MANUAL | ||||

| MAIN BLADE ROTATING SPEED (RPM) | 4000 | ||||

| SCORING UNIT ROTATING SPEED (RPM) | 8000 | ||||

| SAW UNIT MOTOR POWER (S6-40%) KW (HP) | 7.5 HP Hz50 | ||||

| SCORING UNIT MOTOR POWER (S6-40%) KW (HP) | 1 Hp Hz50 | ||||

| SQUARING CAPACITY: WITH 3200 CARRIAGE (MM) | 3200X 375 | ||||

| CUTTING WIDTH ON PARALLEL FENCE (MM) | 1270 | ||||

| EXHAUST OUTLET DIAMETER- AT THEBASE (MM) | ON OVERHEAD PROTECTION (MM) | ON RIVING KNIFE (MM) | 120 | 80 | 60 |

| BASIC MACHINE NET WEIGHT (KG) | 610 kg |

| Panel saw | Unit | Sega315 | Sega350 |

| Blade diameter | mm | Φ(250~315)xΦ30 | Φ(250~350)xΦ30 |

| Main blade speed | r.p.m. | 4000 | 4000 |

| Scoring blade diameter | mm | Φ120xΦ20 | Φ120xΦ20 |

| Scoring blade speed | mm | 8000 | 8000 |

| Max depth of cut at 45° | mm | 75 | 92 |

| Max depth of cut at 90° | mm | 100 | 120 |

| Max rip capacity | mm | 1250 | 1250 |

| Sliding beam size | mm | 3200×375 | 3200×375 |

| Main table size | mm | 910×550 | 910×550 |

| Main extend table size | mm | 910×760 | 910×760 |

| Side extend table size | mm | 500×550 | 500×550 |

| Dust extraction outlet | mm | Φ100 | Φ100 |

| Main motor output | HP – KW | 5,5-4,0 | 7,5-5,5 |

| Scoring motor output | HP – KW | 1,0-0,75 | 1,0-0,75 |

| Net/Gross weight | kg | 610/710 | 630/730 |

| Machine packing size | mm | 2220×1030×1150 | 2220×1030×1150 |

| Sliding table packing size | mm | 3560×420×210 | 3560×420×210 |

| Optional accessories | Unit | Sega350 | Sega350 |

| Single-phase main motor | HP – kW | 4,0 – 3,0 | 4,0 – 3,0 |

| Single-phase scoring motor | HP – kW | 0,75 – 0,5 | 0,75 – 0,5 |

| Dimension Carriage 2800mm | mm | 2800×375 | 2800×375 |

| Dimension Carriage 3800mm | mm | 3800×375 | 3800×375 |

| Motor lifting | ● | ● | |

| CE-type overhead saw blade guard | ● | ● |

400C Combined Machine

The 400C Combined Machine has been specifically designed be an industrial standard machine, but at a size intended for the factory and small professional workshop. This industrially rated machine features a planer, thicknesser and mottiser unit. The cast iron construction, accurate cross cut fence and superb build quality put this machine in a class of its own.

The planer thicknessing function, again is of the highest quality, extremely powerful, accurate and the end result is simply sublime. The inward swing of the thicknessing unit keeps this machine compact in every function,whilst the cast iron construction means even heavy pieces can be handled confidently.

Several further options are also available, each machine can therefore be tailored to the users specific needs.

| Planer | Unit | 400c |

| Working tables | mm | 400×1800 |

| Cutterblock diameter | mm | 70 |

| Cutterblock rotation speed | r.p.m | 5700 |

| N. of knives | n° | 3 |

| knives dimensions | mm | 400x20x3 |

| Max table adjustement | mm | 4 |

| Thicknesser | Unit | 400c |

| Working table | mm | 400×760 |

| Feed speed | m/1′ | 7 |

| Max. working height | mm | 220 |

| Min. working height | mm | 4 |

| Cutterblock rotation speed | r.p.m. | 5700 |

| Max. cutting depth | mm | 4 |

| Mortiser | Unit | 400c |

| Working table | mm | 250×500 |

| Longitudinal stroke | mm | 205 |

| Trasversal stroke | mm | 95 |

| Vertical stroke | mm | 90 |

| Churck | mm | 16 |

| Churck rotation speed | r.p.m. | 5700 |

| Standard accessories | Unit | 400c |

| Service wrenches | * | |

| Mortiser chuck | * | |

| Guards on mortiseur chuck | * | |

| 3 pcs. planing knives | * | |

| Planer guide | * | |

| Bridge sefety hood on planer | * | |

| 3-phase motor power | HP – KW | 4,0 – 3,0 |

| Weight | kg | 385 |

| Optiona accessories | Unit | 400c |

| Single-phase motor | HP – KW | 5,5 – 4,0 |

| Increasing 3-phase motor | HP – KW | 4,0 – 3,0 |

| Wescott(Diameter) | mm | 16 |

C400 Combined Machine

The C400 Combined Machine has been specifically designed be an industrial standard machine, but at a size intended for the factory and small professional workshop. This industrially rated machine features a table saw and sliding table, planer, thicknesser and spindle moulder unit. The cast iron construction, accurate cross cut fence and superb build quality put this machine in a class of its own.

Being a professional standard machine, the C400 of course is fully adjustable and the accuracy is second to none. As far as accuracy goes it will not even be bettered by full sized industrial machines. With three independent class 1 motors providing ample power, changing function can be done with the flick of a switch rather than the going through the laborious task of changing belts.

Features :

- Panel saw sliding beam

- Scoring for veneered boards

- Accurate cross cut fence with flipstops

- Cast iron construction

- Sturdy swinging arm squaring frame

- Inward parallel swing planer table

- 3 x 2.2kw class 1 motors

- Micro adjust spindle moulder fence

- Fully adjustable settings

| Planer | Unit | C400 |

| Working tables | mm | 400×1800 |

| Cutterblock diameter | mm | 70 |

| Cutterblock rotation speed | r.p.m | 5700 |

| N. of knives | n° | 3 |

| knives dimensions | mm | 400x20x3(400x25x3) |

| Max table adjustement | mm | 4 |

| Thicknesser | Unit | C400 |

| Working table | mm | 400×760 |

| Feed speed | m/1′ | 7 |

| Max. working height | mm | 220 |

| Min. working height | mm | 4 |

| Cutterblock rotation speed | r.p.m. | 5700 |

| Max. cutting depth | mm | 4 |

| Mortiser | Unit | C400 |

| Working table | mm | 250×500 |

| Longitudinal stroke | mm | 205 |

| Trasversal stroke | mm | 95 |

| Vertical stroke | mm | 90 |

| Churck | mm | 16 |

| Churck rotation speed | r.p.m. | 5700 |

| Circular saw | Unit | C400 |

| Working table | mm | 326×1112 |

| Shaft rotation speed | r.p.m. | 4500 |

| Blade diameter | mm | 300 |

| Blade bora diameter | mm | 30 |

| Cutting height 90° | mm | 100 |

| Max. distance between blade and fence | mm | 730 |

| Blade inclination | 0° | 45° |

| Max cutting height 45° | mm | 50 |

| Shaft rotation speed engraver | r.p.m. | 7000 |

| Engraver blade diameter | mm | 90 |

| Engraver blade bora diameter | mm | 22 |

| Shaper | Unit | C400 |

| Working tables | mm | 326×1112 |

| Shaft rotation speeds | r.p.m. | 2000/3100/4400/7000 |

| Standard shaft diameter | mm | 30 |

| Spindle lenght | mm | 105 |

| Shaft vertical stroke | mm | 115 |

| Max. tool diameter | mm | 180 |

| Max. tenoning depth | mm | 65 |

| Tenoning carriage | Unit | C400 |

| Carriage dimensions | mm | 1800×315 |

| Carriage stroke | mm | 1800/2200 |

| Standard accessories | Unit | C400 |

| N°2 clamp lever | * | |

| Sharper fence | * | |

| Service wrenches | * | |

| Mortiser chuck | * | |

| Table extensions with swinging arms | mm | 860×600 |

| Guards on mortiseur chuck | * | |

| 3 pcs. planing knives | * | |

| Planer guide | ||

| Saw guide | ||

| Bridge sefety hood on planer | * | |

| 3-phase motor power | HP – KW | 4,0 – 3,0 |

| Weight | kg | 645 |

| Optiona accessories | Unit | C400 |

| Single-phase motor | HP – KW | 4,0 – 3,0 |

| Increasing 3-phase motor | HP – KW | 5,5 – 4,0 |

| Set of wheels with feeding steering bar | * | |

| Wescott(Diameter) | mm | 16 |

| Carriage stroke | mm | 2200/2200 |

| Carriage stroke | mm | 2600/2600 |

| Tenoning with protection shelf |

Universal Combination M/c

1 machine, that work as 5 machines!

Specifically designed to be an industrial standard m/c, but at a size intended for the factory and small professional workshop.

Salient Features :

- Panel saw sliding table

- Scoring for laminate boards

- Accurate cross cut fence with flip stops

- Cast iron construction

| Model | J-4030 |

| Surface Planer | mm |

| Surfacing capacity | 300 |

| Length of surface table | 1500 |

| Cutter block diameter | 70 |

| Cutter block speed-rpm | 5700 |

| Max table adjustment | 4 |

| Thicknesser | |

| Max Planing width | 300 |

| Length of thickness table | 660 |

| Feed speed-meter/min | 7 |

| Working height Min – Max | 4 – 220 |

| Circular saw | |

| Sliding table size | 220×1600 |

| Main Saw / Scoring Saw speed -rpm | 4500/7000 |

| Main Saw blade diameter x bore | 250×30 |

| Cutting height at 45°/90° | 50/80 |

| Cutting width parallel fence | 500 |

| Scoring blade diameter x bore | 90×22 |

| Spindle Moulder | |

| Sliding table size | 220×1600 |

| Spindle speeds -rpm | 2000/3100/4400/7000 |

| Standard shaft diameter | 30 |

| Up-down movement of spindle | 115 |

| Max. tool diameter | 160 |

| Max. tenoning depth | 55 |

| Mortiser | |

| Working table | 250×500 |

| Longitudinal/Transversal/Vertical stroke | 205/95/90 |

| Chuck (M18*1.5-S) | 0-16 |

| Standard Accessories | |

| 3-phase motor power- no x hp | 3 x 3 |

| Approx. weight of m/c -kg | 560 |

Combiplaner-S (Open Stand)

Almost a portable work-station… at a moderate bugdet

Useful multi-functionality of combiplaner, in value-for-money machines of this series. These are preferred by wood-working workshops for its enhanced utility, trusted performance and rugged durability. These m/cs are suitable for portability in a moderate budget.

| Model | J-302 |

J-303 |

J-303 L |

mm/inch |

mm/inch |

mm/inch |

|

| Surfacing capacity | 254 / 10″ |

330 / 13″ |

330 / 13″ |

| Max planing width | 254 / 10″ |

330 / 13″ |

330 / 13″ |

| Thicknessing capacity | 177 / 7″ |

177 / 7″ |

177 / 7″ |

| Length Of surface Table | 1140 / 45″ |

1220 / 48″ |

1550 / 61″ |

| Rebating Capacity | 12.5 / ½” |

12.5 / ½” |

12.5 / ½” |

| Length Of Thickness Table | 610 / 24″ |

660 / 26″ |

660 / 26″ |

| Min. Length of workpiece for thicknessing | 254 / 10″ |

254 / 10″ |

254 / 10″ |

| Feeding Speed (feet per minute) | 24 |

24 |

24 |

| Cutter block diameter | 95 / 3.75″ |

95 / 3.75″ |

95 / 3.75″ |

| Cutter block speed- RPM | 4000 |

4000 |

4000 |

| Standard cutter block – code no. | 2B |

3B-W |

3B-W |

| Circular saw table size | 560 x 280 / 22″ x 11″ |

560 x 280 / 22″ x 11″ |

560 x 280 / 22″ x 11″ |

| Up/Down movement of Cir.saw table | 75 / 3″ |

75 / 3″ |

75 / 3″ |

| Max.circular saw diameter | 300 / 12″ |

300 / 12″ |

300 / 12″ |

| Power required – HP / RPM | 2 / 1440 |

3 / 1440 |

3 / 1440 |

| Approx.wt.of machine – kg. | 280 |

320 |

350 |

Combiplaner-S

Preferred for its Multi faceted utility, performance and rugged durability

These are preferred by wood-working workshops for its enhanced utility, trusted performance and rugged durability.

| Model | J-701P |

J-702 |

J-703 |

mm/inch |

mm/inch |

mm/inch |

|

| Surfacing capacity | 330 / 13" |

455 / 18" |

610 / 24" |

| Max planing width | 330 / 13" |

455 / 18" |

610 / 24" |

| Thicknessing capacity | 200 / 8" |

200 / 8" |

200 / 8" |

| Length Of surface Table | 1220 / 48" |

1550 / 61" |

1550 / 61" |

| Rebating Capacity | 12.5 / ½" |

12.5 / ½" |

12.5 / ½" |

| Length Of Thickness Table | 660 / 26" |

760 / 30" |

915 / 36" |

| Min. Length of workpiece for thicknessing | 254 / 10" |

254 / 10" |

254 / 10" |

| Feeding Speed (feet per minute) | 24 |

24 |

24 |

| Cutter block diameter | 120 / 4.72" |

120 / 4.72" |

120 / 4.72" |

| Cutter block speed- RPM | 4000 |

4000 |

4000 |

| Standard cutter block – code no. | 3B-W |

3B-W |

3B-W |

| Circular saw table size | 610 x 355 / 24" x 14" |

610 x 355 / 24" x 14" |

610 x 355 / 24" x 14" |

| Up/Down movement of Cir.saw table | 75 / 3" |

75 / 3" |

75 / 3" |

| Max.circular saw diameter | 300 / 12" |

300 / 12" |

300 / 12" |

| Power required – HP / RPM | 3 / 1440 |

5 / 1440 |

5 / 1440 |

| Approx.wt.of machine – kg. | 500 |

700 |

850 |

Minimax ®

For the professionals who value multi-functionality and precision workmanship

Combiplaners are combined Surfacer & Thicknesser m/cs. This is same high value machine like Combimax, but with fix top for site work. Combining precision and multi functionality in a machine that can work wonders for a professional set-up.

| Model | J-1010 |

mm / inch |

|

| Surfacing capacity | 254 / 10″ |

| Max planing width | 254 / 10″ |

| Thicknessing capacity | 177 / 7″ |

| Length Of surface Table | 1140 / 45″ |

| Rebating Capacity | 12.5 / ½” |

| Length Of Thickness Table | 635 / 25″ |

| Min. Length of workpiece for thicknessing | 254 / 10″ |

| Feeding Speed (feet per minute) | 24 |

| Cutter block diameter | 95 / 3.75″ |

| Cutter block speed- RPM | 4000 |

| Standard cutter block – code no. | 2B |

| Circular saw table size | 610 x 315 / 24″ x 12″ |

| Up/Down movement of Cir.saw table | 75 / 3″ |

| Max.circular saw diameter | 300 / 12″ |

| Power required – HP / RPM | 3 / 1440 |

| Approx.wt.of machine – kg. | 350 |

Max-13 ™, Max-15 ®, Max-18 ™,Max-24 ™

For the professionals who value multi-functionality and precision workmanship

Combiplaners are combined Surfacer & Thicknesser m/cs. These are same high value machines like Combimax, but with fixed top. Combining precision and multi functionality in a machine that can work wonders for a professional set-up.

Max-13 |

Max-13 |

Max-15 |

Max-15 |

Max-18 |

Max-24 |

|

| Model | J-1014 |

J-1014L |

J-1015 |

J-1015L |

J-1019 |

J-1025 |

mm / inch |

mm / inch |

mm / inch |

mm / inch |

mm / inch |

mm / inch |

|

| Surfacing capacity | 330 / 13″ |

330 / 13″ |

381 / 15″ |

381 / 15″ |

455 / 18″ |

610 / 24″ |

| Max planing width | 330 / 13″ |

330 / 13″ |

381 / 15″ |

381 / 15″ |

455 / 18″ |

610 / 24″ |

| Thicknessing capacity | 177 / 7″ |

177 / 7″ |

177 / 7″ |

177 / 7″ |

177 / 7″ |

177 / 7″ |

| Length Of surface Table | 1220 / 48″ |

1550 / 61″ |

1295 / 51″ |

1550 / 61″ |

1550 / 61″ |

1550 / 61″ |

| Rebating Capacity | 12.5 / ½” |

12.5 / ½” |

12.5 / ½” |

12.5 / ½” |

12.5 / ½” |

12.5 / ½” |

| Length Of Thickness Table | 640 / 25¼” |

640 / 25¼” |

710 / 28″ |

710 / 28″ |

735 / 29″ |

800 / 31½” |

| Min. Length of workpiece for thicknessing | 254 / 10″ |

254 / 10″ |

254 / 10″ |

254 / 10″ |

254 / 10″ |

254 / 10″ |

| Feeding Speed (feet per minute) | 24 |

24 |

24 |

24 |

24 |

24 |

| Cutter block diameter | 95 / 3.75″ |

95 / 3.75″ |

95 / 3.75″ |

95 / 3.75″ |

105 / 4.15″ |

120 / 4.72″ |

| Cutter block speed- RPM | 4000 |

4000 |

4000 |

4000 |

4000 |

4000 |

| Standard cutter block – code no. | 2B |

2B |

2B |

2B |

3B-W |

3B-W |

| Circular saw table size | 610 x 305 / 24″ x 12″ |

610 x 305 / 24″ x 12″ |

610 x 305 / 24″ x 12″ |

610 x 305 / 24″ x 14″ |

610 x 355 / 24″ x 14″ |

610 x 355 / 24″ x 14″ |

| Up/Down movement of Cir.saw table | 75 / 3″ |

75 / 3″ |

75 / 3″ |

75 / 3″ |

75 / 3″ |

75 / 3″ |

| Max.circular saw diameter | 300 / 12″ |

300 / 12″ |

300 / 12″ |

300 / 12″ |

300 / 12″ |

300 / 12″ |

| Power required – HP / RPM | 3 / 1440 |

3 / 1440 |

3 / 1440 |

3 / 1440 |

5 / 1440 |

5 / 1440 |

| Approx.wt.of machine – kg. | 400 |

420 |

450 |

475 |

600 |

750 |

Combimax

For the professionals who value multi-functionality and precision workmanship

Combi Planer are combined Surfacer & Thicknesser m/cs. Combimax has the highest features in this range. Combining precision and multi functionality in a machine that can work wonders for a professional set-up.

Combimax |

|||||||||||

| Model | J-1013 |

J-1013 L |

J-1018 |

J-1018 LL |

|||||||

mm / inch |

mm / inch |

mm / inch |

mm / inch |

||||||||

| Surfacing capacity | 330 / 13″ |

330 / 13″ |

455 / 18″ |

455 / 18″ |

|||||||

| Max planing width | 330 / 13″ |

330 / 13″ |

455 / 18″ |

455 / 18″ |

|||||||

| Thicknessing capacity | 177 / 7″ |

177 / 7″ |

177 / 7″ |

177 / 7″ |

|||||||

| Length Of surface Table | 1220 / 48″ |

1550 / 61″ |

1550 / 61″ |

1830 / 72″ |

|||||||

| Rebating Capacity | 12.5 / ½” |

12.5 / ½” |

9 / ⅜” |

9 / ⅜” |

|||||||

| Length Of Thickness Table | 560 / 22″ |

710 / 28″ |

660 / 26″ |

810 / 32″ |

|||||||

| Min. Length of workpiece for thicknessing | 254 / 10″ |

254 / 10″ |

254 / 10″ |

254 / 10″ |

|||||||

| Feeding Speed (feet per minute) | 21 |

21 |

21 |

21 |

|||||||

| Cutter block diameter | 95 / 3.75″ |

95 / 3.75″ |

95 / 3.75″ |

95 / 3.75″ |

|||||||

| Cutter block speed- RPM | 4000 |

4000 |

4000 |

4000 |

|||||||

| Standard cutter block – code no. | 2B |

2B |

3B-W |

3B-W |

|||||||

| Circular saw table size | 610×305

/ 24″ x 12″ |

610×305

/ 24″ x 12″ |

610×305

/ 24″ x 12″ |

610×305

/ 24″ x 12″ |

|||||||

| Up/Down movement of Cir.saw table | 75 / 3″ |

75 / 3″ |

75 / 3″ |

75 / 3″ |

|||||||

| Max.circular saw diameter | 300 / 12″ |

300 / 12″ |

300 / 12″ |

300 / 12″ |

|||||||

| Power required – HP / RPM | 3 / 1440 |

3 / 1440 |

5 / 1440 |

5 / 1440 |

|||||||

| Approx.wt.of machine – kg. | 450 |

475 |

600 |

650 |

|||||||

Combiplaner

Preferred by wood-working workshops for its Precision workmanship,Multi-faceted utility, trusted performance and rugged durability

These are preferred by wood-working workshops for its enhanced utility, trusted performance and rugged durability.

Model |

J-4018 |

mm/inch |

|

Surfacing Capacity |

455 / 18" |

Max Planing width |

455 / 18" |

Thicknessing Capacity |

200 / 8" |

Length Of surface Table |

2130 / 84" |

Length Of Thickness Table |

775 / 30½" |

Min. Length of work piece for thicknessing |

254 / 10" |

Feeding Speed (feet per minute) |

24 |

Cutter block diameter |

95 / 3¾" |

Cutter block speed- RPM |

4000 |

Standard cutter block – code no. |

3B-W |

Size of Dust Collection Port-Dia. |

100 / 4" |

Power required – HP / RPM |

5 / 1440 |

Approx.wt.of machine – kg. |

800 |

Panel Process Machines

Salient Features :

- Sturdily built heavy duty machine to suit Indian working condition for precise cut with burr free cutting

- Lifting and tilting of saw unit by means of hand wheels on the machine. Both on front side for more convenience

- Electronic Digital readout of saw unit tilt

- Rip fence with fine setting for precise positioning

- Made in India with best service support & very economical spares

| Specifications | Unit | Technical Parameters | |

| Sliding Table | |||

| 1. | Sliding Table Length | mm | 3200 |

| 2. | Sliding Table Length | mm | 360 |

| Main Saw Unit | |||

| 3. | 3 Max. Diameter Saw Blad | mm | 355 x 30 |

| 4. | 4 Saw Blade Speed | rpm | 4000 / 5000 |

| 5. | Tilting of Saw Blade | degree | 90° – 45° (manual) electronic digital read out |

| 6. | Max. Cutting Depth at 90° | mm | 102 |

| 7. | Max. Cutting Depth at 45° | mm | 72 |

| 8. | Up-Down movement of saw blade | manual | |

| 9. | Motor For Saw Blade | hp | 7.5 |

| Scoring Saw Unit | |||

| 10. | Max. Diameter Scoring Blade | mm | 120/20 |

| 11. | Scoring Blade Speed | rpm | 8500 |

| 12. | Tilting of Scoring Blade | degree | 90° – 45° (manual) electronic digital read out |

| 13. | Up-Down movement of scoring blade | manual | |

| 14. | Lateral Adjustment Scoring Blade | mm | ± 3 |

| 15. | Max. Depth of Cut off Scoring Blade | mm | 5 |

| 16. | Motor For Scoring Unit | hp | 1 |

| Other Specifications | |||

| 17. | Cutting Width / Rip Capacity | mm | 1250 |

| 18. | Dimension Main Saw Table | mm | 560 x 900 |

| 19. | Length Cross – Cut Fence | mm | 2000 |

| 20. | Dust extraction port diameter | mm | 100 & 50 |

| 21. | Machine Dimension (L x B x H) | mm | 3400 x 3710 x 1300 |

| 22. | Approx. Net Weight | kg | 850 |

Filter

Belt

Bearings

Paper Filter

Glass sand blasting machine

This machine is used to sand blasting patterns or trademark on glass surface. Or sand blast the whole surface for separate wall and shower room door.

| Model Number | YD-SB-1500 | YD-SB-2000 | YD-SB-2500 |

| Max. glass height (mm) | 15000 | 2000 | 2500 |

| Min. processing size (mm) | 200×500 | 200×500 | 200×500 |

| Glass transfer speed m/min | 5 m/min | 5 m/min | 5 |

| Nozzle moving speed m/min | 5-25 | 5-25 | 5-25 |

| Suitable working pressure: continues | 0.6MPa~0.8MPa | 0.6MPa~0.8MPa | 0.6MPa~0.8MPa |

| Suitable air pressure power | 2.4 m3/min 15kw | 2.4 m3/min 15kw | 2.4 m3/min,15kw |

| Power (kw) | 3.5KW | 3.5KW | 3.5KW |

| Outer dimension (m) | 4.5 x 1.5 x 2 | 7.0 x1.5 x 2.8 | 8.0 x1.5 x 3.3 |

| Weight (kg) | 1000 | 1500 | 2000 |

Aluminium double head cutter

Thicknesser

| Model | TH400 | TH500 | TH630 |

|---|---|---|---|

| Max.planing width | 400mm | 500mm | 630mm |

| Planing thickness | 4-200mm | 4-200mm | 4-200mm |

| Min.planing length | 220mm | 220mm | 220mm |

| Feeding speed | 8; 12 m/min | 8 ; 12 m/min | 8; 12m/min |

| Max.planing depth | 5mm | 5mm | 5mm |

| Spindle speed | 4800 r/min | 4800 r/min | 5500r/min |

| Blade number | 4 | 4 | 4 |

| Spindle dia. | 105mm | 105mm | 105mm |

| Motor | 5.5kW , 380V | 5.5kW, 380V | 7.5kW, 380V | Net. weight | 405kg | 445kg | 494kg |

| Overall dimensions | 823x884x1143mm | 923x884x 1143mm | 1053x894x1 143mm |

Surface Planer

| Model | MB524M |

|---|---|

| Model Number | YD-SB-1500 |

| Max.planing | width 400mm |

| Max.planing depth | Smm |

| Spindle speed | 5000r/min |

| Blade number | 4 |

| Cutting dia. | 102mm |

| Table size | 2000mm |

| Motor power | 3kW , 380V |

| Net.weight | 391kg |

| Overall dimensions | 2000x790x1100mm |

Spindle Moduler

| Model | TP117 | TP117 PRO |

|---|---|---|

| Spindle speed | 10000/8000/6000 r/min | 10000/8000/6000 r/min |

| Spindle speed | 10000/8000/6000 r/min | 10000/8000/6000 r/min |

| Spindle dia. | 35 mm(Order) | 35 mm (Order) |

| Max.milling thickness | 120 mm | 120 mm |

| Motor power | 4 kW(5.5 kW optional) | 4 Kw(5.5 kW optional) |

| Table size | 1130x670mm | 1130x410mm |

| Sliding table size | – | 1130x260mm |

| Max.stroke sliding table | – | 780mm |

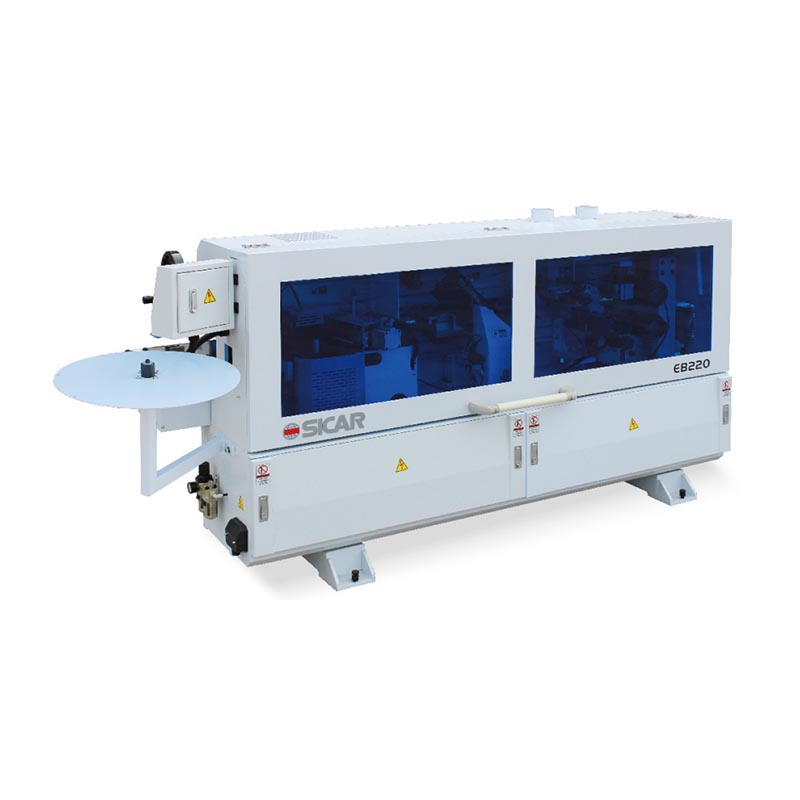

Edge Banding

| Model | EB220 | EB280 |

|---|---|---|

| Thickness of roling edge-banding belt | 0.4-3mm | 0.4-3mm |

| Height of roling edge-banding belt | 12-45mm | 12-45mm |

| Workpiece thickness | 10-45mm | 10-45mm |

| Air pressure | 0.6-0.8Mpa | 0.6-0.8Mpa |

| Gross power | 6kW | 6.5kW |

| Machine outline size | 2450x680x1280mm | 2600x600x1400mm |

| Weight | 700Kg | 750Kg |

HOT PRESS NPC DIGIT 3500/S ORMAMACCHINE

Hot press NPC 3500/S DIGIT de ORMAMACCHINE: platen 3500×1300 mm, total thrust 90 Tn, 6 pistons, stroke 400mm, motor power 2 HP. Oil boiler 120º or Water boiler 90º or electric platens.

TECHNICAL DATA

- Platen sizes (mm.): 3500×1300

- Total thrust (Tons.): 90

- Cylinders: 6

- Diam. Pistons: 70

- Stroke:400/650

- Pressure (kg/cm2): 2,4

- Motor (HP): 4

- Wood (kcal/h): 29.900

- Boiler (Kw): 21

- Electric platens (Kw): 28,8

- Overall Dimensions: 4150x1650x2200

- Net weight (Kg): 4150

TECHNICAL FEATURES

- Hot presses NPC fabricated assembled steel platens or drilled solid steel platens

- Water boiler 90ºC or oil boiler 120ºC

- The press is complete with pump, boiler and pipes

- The presses of the NPC-DIGIT series are complete with automatic recuperator of the possible pressure loss (it works leaving current on.

- Max. working pressure 350 At

- Standard emergency rope

- Digital display for:

- Setting out and digital visualization of the working pressure

- Setting out and digital visualization of the working temperature (for presses with electric boiler)

- Setting out and digital visualization of the timer to adjust pressing duration

- Digital setting out of the automatic switching on of the heating installation (for presses with electric boiler)

- Possibility to set out all week days

- Selection ON/OFF to operate the exclusion of 2 pressing pistons (the exclusion is standard on presses with 8/10 pistons and optional on the 6-piston version)

- Setting out of the electric consumption of boilers (for powers more than 20 kW)

OPTIONAL

- Intermediate platen

- Mylar

- Electric platens (without any boiler)

Aluminum cutter thomas

Profile bending machine

End Milling

Air Compressor

Screw compressor

Air Dryer